Contents

- 1 Mastering the Roots and Harvest of Chicken Plucker: The Ultimate Guide

- 2 The Importance of Roots in Chicken Plucker Efficiency

- 3 Harvesting Techniques for Maximum Chicken Plucker Yield

- 4 Innovations in Chicken Plucker Technology

- 5 FAQ

- 5.1 How can I ensure that the roots of my chicken plucker are strong and sturdy enough to handle the weight and movement of the machine during the harvesting process?

- 5.2 What are some of the best practices for harvesting chickens using a chicken plucker, in order to maximize efficiency and ensure the highest quality plucked birds?

- 5.3 Are there specific varieties of chicken that are better suited for use with a chicken plucker, in terms of feather density and ease of plucking?

- 5.4 Related Posts

Are you tired of spending hours plucking chickens by hand? Look no further! Our blog, , is here to introduce you to the amazing world of roots and harvest chicken pluckers. Whether you’re a backyard farmer or a seasoned poultry enthusiast, this article will provide you with valuable insights and tips on how to achieve efficient and time-saving plucking results. Say goodbye to tedious manual plucking and say hello to the future of chicken processing!

Mastering the Roots and Harvest of Chicken Plucker: The Ultimate Guide

Mastering the Roots and Harvest of Chicken Plucker: The Ultimate Guide

In the world of chicken plucking, understanding the roots and harvest of this process is vital for success. Whether you are a novice or an experienced plucker, honing your skills and knowledge will elevate your efficiency and productivity.

One important aspect to master is the anatomy of a plucker. Knowing how each part works and contributes to the overall operation will enhance your ability to troubleshoot issues and ensure optimal performance. From the motor to the rotating fingers, every component plays a significant role in achieving clean and efficient plucking.

Regular maintenance is another crucial factor to consider. Keeping your plucker in top condition will extend its lifespan and minimize downtime. Regularly inspecting and cleaning each part, lubricating where necessary, and replacing worn-out components will guarantee smooth operations and maximize productivity.

The harvest process itself requires attention to detail and precision. Understanding the best time to pluck chickens, proper handling techniques, and appropriate post-plucking care will ensure the highest quality product. Additionally, implementing effective sanitation practices throughout the harvest process is essential for food safety and compliance with regulations.

Investing in training and education is key to becoming a skilled chicken plucker. With various resources available, such as online courses, workshops, and industry publications, you can continuously expand your knowledge and stay up to date with the latest advancements in plucking techniques and equipment.

Lastly, always remember to seek inspiration and guidance from fellow chicken pluckers. Networking with like-minded individuals, joining forums and communities can provide valuable insights, tips, and tricks that can take your plucking game to the next level.

By mastering the roots and harvest of chicken plucking, you are setting yourself up for success in this specialized field. Continuously improving your skills, keeping your equipment in pristine condition, and staying informed on industry trends will ensure that you achieve the best results in your chicken plucking endeavors.

The Importance of Roots in Chicken Plucker Efficiency

Roots: A Key Factor in Efficiency

When it comes to chicken plucking, the condition and quality of the roots play a crucial role in determining the overall efficiency of the process. Healthy and well-established roots ensure a firm grip, which allows the plucker fingers to efficiently remove feathers without causing damage to the chicken’s skin. The presence of strong roots also minimizes the risk of feathers getting stuck or clogged in the plucking machine. Therefore, it is important to understand and prioritize root health for optimal chicken plucker performance.

Factors Affecting Root Health

There are several factors that can affect the health of roots, such as soil quality, moisture levels, and proper nutrition. Ensuring the right pH balance, adequate water supply, and appropriate fertilization can greatly contribute to root development. Additionally, regular maintenance practices, including routine inspections, watering schedules, and disease prevention measures, are essential in promoting strong and healthy roots.

Tips for Promoting Healthy Roots

To enhance the efficiency of your chicken plucker, here are some tips for promoting healthy roots:

– Use organic compost or fertilizers rich in nutrients to improve soil fertility

– Regularly water the plants to maintain optimal moisture levels

– Implement a proper drainage system to prevent waterlogging, which can negatively impact root health

– Monitor and address any signs of diseases or pests promptly

– Periodically inspect the roots for signs of damage or weakness and take necessary action

By focusing on the health of the roots, chicken plucker efficiency can be significantly improved, resulting in a smoother and more effective plucking process.

Harvesting Techniques for Maximum Chicken Plucker Yield

Optimizing Harvesting Time

The timing of the chicken harvest can have a significant impact on the yield achieved with a chicken plucker. The ideal time for harvesting is when the chickens have reached their maximum size but have not yet started to molt. This ensures that the feathers are firmly attached, allowing the plucking machine to effectively remove them with minimal effort. Harvesting at the right time also prevents excessive feather loss, which can reduce the overall yield.

Proper Handling and Feather Removal

In addition to timing, proper handling of the chickens during the harvesting process is essential for maximum yield. Gentle yet firm handling minimizes stress and reduces the risk of feather damage or loss. When using a chicken plucker, it is important to position the chickens correctly, ensuring that all feathers come into contact with the plucking fingers for thorough removal. Care should also be taken to remove any remaining feathers manually after the plucking process to achieve a clean and presentable end product.

Cleaning and Maintenance

Regular cleaning and maintenance of the chicken plucker are crucial for maintaining its efficiency and ensuring maximum yield. Keep the plucking fingers clean and free from debris to prevent clogging, which can reduce the plucker’s performance. Regularly inspect the plucking machine for any signs of wear or damage, and replace worn-out parts as necessary. Adequate lubrication of moving parts further enhances the performance and longevity of the chicken plucker.

By applying proper harvesting techniques, handling, and maintenance practices, you can optimize the yield achieved with a chicken plucker and maximize the efficiency of the process.

Innovations in Chicken Plucker Technology

The Evolution of Chicken Pluckers

Chicken plucker technology has come a long way, with continuous innovations aimed at improving efficiency and productivity. From traditional hand-operated pluckers to modern mechanized solutions, advancements have revolutionized the poultry processing industry. Newer chicken pluckers incorporate features like adjustable plucking speeds and gentle feather removal techniques, minimizing damage to the chicken’s skin. These technological advancements not only enhance efficiency but also improve the overall quality of the final product.

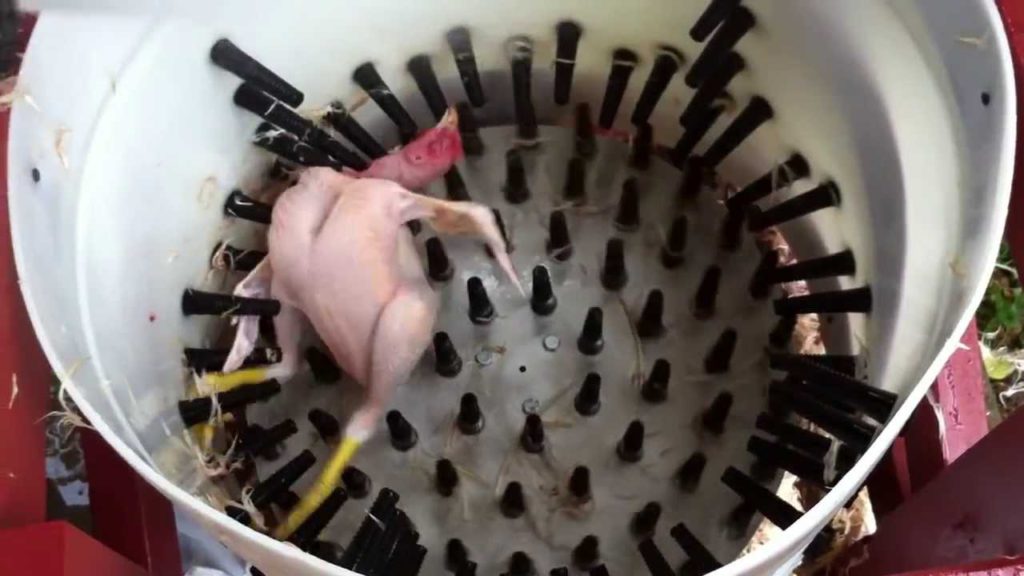

Automated Plucking Machines

The advent of automated chicken plucker machines has significantly increased efficiency in large-scale poultry processing operations. These machines are designed to handle high volumes of chickens, reducing labor requirements and processing time. Many automated plucking machines utilize rotating rubber fingers or soft rubber discs that mimic the natural plucking motion, ensuring thorough feather removal while maintaining the integrity of the chicken’s skin. Some advanced models also incorporate sensors and intelligent controls to optimize performance and minimize downtime.

Environmental Considerations

In recent years, there has been a growing focus on developing eco-friendly chicken plucker solutions. Manufacturers are increasingly prioritizing energy efficiency and waste reduction in their designs. Efforts are being made to minimize water usage during the plucking process and incorporate recycling systems to reduce environmental impact. Additionally, the use of biodegradable and sustainable materials in the construction of plucking fingers and machine components is being explored.

As technology continues to advance, we can expect further innovations in chicken plucker technology, ultimately leading to more efficient, sustainable, and user-friendly solutions.

FAQ

How can I ensure that the roots of my chicken plucker are strong and sturdy enough to handle the weight and movement of the machine during the harvesting process?

To ensure that the roots of your chicken plucker are strong and sturdy enough to handle the weight and movement of the machine during the harvesting process, consider the following key factors:

1. Quality of materials: Choose high-quality and durable materials for constructing the roots of your chicken plucker. This includes using sturdy metal or reinforced plastic components that can withstand the stress and pressure exerted during the operation.

2. Proper structural design: Ensure that the roots are designed with appropriate bracing and reinforcement to distribute the weight evenly and prevent any weak points or potential failure areas. Consider incorporating cross supports and struts to enhance stability.

3. Secure anchoring: Install the roots firmly in place to prevent any shifting or instability during use. Anchor them securely to a solid base or foundation using bolts, screws, or other appropriate fasteners. This will help to maintain the overall stability of the machine.

4. Regular maintenance: Implement a routine maintenance schedule to inspect and reinforce the roots as necessary. Check for any signs of wear, loosening, or damage and promptly address them to prevent further deterioration or potential accidents.

5. Weight distribution: Ensure that the weight of the machine, including the motor and rotating components, is well-distributed across the roots. Avoid placing excessive weight on any single point to prevent overloading and potential failure.

Remember, the strength and sturdiness of the roots are crucial for the safe and efficient operation of the chicken plucker. Therefore, it is important to prioritize the quality of materials, proper design, secure anchoring, regular maintenance, and proper weight distribution to maximize the longevity and performance of your machine.

What are some of the best practices for harvesting chickens using a chicken plucker, in order to maximize efficiency and ensure the highest quality plucked birds?

1. Preparing the chickens: Prior to plucking, make sure the chickens have been properly processed and cleaned. This includes bleeding them out, removing feathers from the head and neck, and eviscerating them if necessary.

2. Scalding: Heat up a large pot of water to around 145-150°F (63-66°C) and immerse the chickens in it for about 1-2 minutes. This helps to loosen the feathers and makes plucking easier.

3. Plucking: Place the chickens one at a time into the chicken plucker machine. Ensure that the chickens are securely held in place before turning on the machine. The plucker will use rubber fingers or rubber discs to remove the feathers effectively. Rotate the chickens gently as needed to ensure thorough plucking.

4. Proper maintenance: Regularly clean and maintain the chicken plucker to keep it in optimal working condition. This includes checking and replacing any worn-out rubber fingers or discs to maintain efficient feather removal.

5. Quality control: Inspect each chicken after plucking to ensure all feathers have been removed. Any remaining feathers can be removed manually using pliers or other tools.

6. Chilling and storage: After plucking, chill the chickens immediately to bring down their temperature and preserve freshness. Store the plucked birds in a clean and hygienic environment, such as a refrigerated space, until further processing or packaging.

7. Safety precautions: Always follow safety guidelines when using a chicken plucker, such as wearing protective gloves and ensuring proper grounding of electrical equipment.

By following these best practices, you can maximize efficiency and ensure the highest quality plucked birds when using a chicken plucker.

Are there specific varieties of chicken that are better suited for use with a chicken plucker, in terms of feather density and ease of plucking?

There are certain chicken breeds that are considered more suitable for use with a chicken plucker due to their feather density and ease of plucking. Some popular breeds that are known to have loose feathers and are easier to pluck include White Leghorns, Cornish Cross, and Red Rangers. These breeds often have less dense feather coverage, making the plucking process more efficient. However, it is important to note that individual variations within a breed can also determine the plucking experience. Overall, choosing a breed with looser feathers can greatly improve the efficiency and ease of using a chicken plucker.

The roots and harvest chicken plucker provides a groundbreaking solution for poultry farmers. Its efficient design and advanced technology ensure a seamless plucking process. The use of high-quality materials guarantees durability and longevity, making it a wise investment. Additionally, its user-friendly interface and easy maintenance make it suitable for farmers of all levels of experience. With the roots and harvest chicken plucker, poultry farmers can significantly reduce their labor and time, ultimately boosting productivity and profitability. Embrace this innovative tool and experience the convenience and efficiency it offers to revolutionize your chicken plucking operations.