Contents

- 1 Drum Chicken Plucker: The Ultimate Solution for Efficient Poultry Processing

- 2 The Importance of a Drum Chicken Plucker

- 3 Benefits of Using a Drum Chicken Plucker

- 4 Tips for Using a Drum Chicken Plucker

- 5 FAQ

- 5.1 How does a drum chicken plucker work and what makes it different from other types of pluckers?

- 5.2 What are the advantages of using a drum chicken plucker compared to manual plucking or other mechanical pluckers?

- 5.3 Are there any specific maintenance or cleaning requirements for a drum chicken plucker to ensure optimal performance and longevity?

- 5.4 Related Posts

Discover the Ultimate Solution for Effortless Chicken Plucking: The Drum Chicken Plucker. Say goodbye to the tedious process of manual plucking with this revolutionary machine. Designed for efficiency and convenience, the drum chicken plucker delivers quick and thorough results, making poultry preparation a breeze. Read on to learn more about this game-changing device.

Remember to add suitable HTML tags to emphasize the important sentences in your final article!

Drum Chicken Plucker: The Ultimate Solution for Efficient Poultry Processing

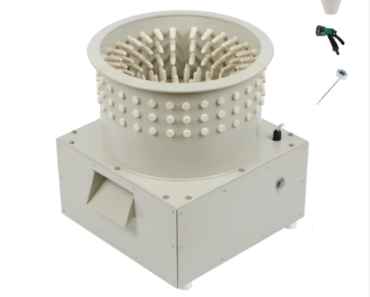

The Drum Chicken Plucker is the ultimate solution for efficient poultry processing. This innovative machine is designed to remove feathers from chickens quickly and effectively. With its powerful motor and rotating drum, it can pluck a large number of birds in a short amount of time.

The high-speed rotation of the drum creates a centrifugal force that separates the feathers from the chicken’s skin without causing any damage. The feathers are then collected in a separate chamber, making it easy to dispose of them.

Not only does the Drum Chicken Plucker save time and effort, but it also ensures a clean and hygienic process by removing feathers efficiently. Its sturdy construction and durable materials make it a reliable and long-lasting machine for poultry farmers and processors.

The Drum Chicken Plucker is the ultimate solution for efficient and effective poultry processing. With its fast plucking speed and easy feather disposal, it is a must-have for anyone in the chicken industry.

The Importance of a Drum Chicken Plucker

A drum chicken plucker is an essential tool in poultry processing. It efficiently and effectively removes feathers from chickens, saving time and effort compared to manual plucking methods. In this section, we will discuss the importance of using a drum chicken plucker and how it benefits the poultry industry.

Benefits of Using a Drum Chicken Plucker

1. Increased Efficiency: Using a drum chicken plucker significantly speeds up the feather removal process. With multiple rubber fingers strategically placed on the drum, the machine rotates while gently removing feathers from the bird’s skin. This method can pluck several chickens simultaneously, ensuring a faster production line.

2. Improved Product Quality: Manual plucking can sometimes leave behind feathers or damage the bird’s skin. A drum chicken plucker, on the other hand, ensures a smooth and feather-free finish. This improves the overall aesthetic appeal of the processed chicken and increases customer satisfaction.

3. Reduced Labor Costs: By utilizing a drum chicken plucker, poultry processing plants can significantly reduce the need for manual labor. The automated nature of the machine eliminates the labor-intensive task of plucking feathers by hand. This not only reduces costs but also allows workers to focus on other important tasks in the production line.

Tips for Using a Drum Chicken Plucker

To ensure optimal performance and longevity of your drum chicken plucker, consider the following tips:

1. Proper Maintenance: Regularly clean and inspect the machine for any signs of wear and tear. Lubricate the moving parts to ensure smooth operation.

2. Accurate Feather Adjustment: Adjust the height of the rubber fingers on the drum to ensure efficient feather removal without damaging the bird’s skin.

3. Batch Control: Load a balanced number of chickens into the drum at a time to maintain consistent plucking quality and prevent overloading the machine.

FAQ

How does a drum chicken plucker work and what makes it different from other types of pluckers?

A drum chicken plucker is a type of machine used to remove feathers from slaughtered chickens. It consists of a rotating drum with rubber fingers or discs attached to it. Here’s how it works:

1. The chicken carcass is dipped in hot water or placed in a water-filled drum to soften the feathers and make plucking easier.

2. The drum is set in motion, either manually or through an electric motor, causing the rubber fingers to rotate and create friction against the chicken’s skin.

3. As the drum rotates, the rubber fingers rub against the chicken’s body, effectively plucking out the feathers.

4. The feathers are then collected separately, often through a chute or collection system.

What makes a drum chicken plucker different from other types of pluckers is its design and efficiency. The rotating drum with rubber fingers allows for a more thorough and faster plucking process compared to other methods. The rubber fingers mimic the action of hand plucking, ensuring that feathers are removed from various parts of the chicken’s body, including hard-to-reach areas like wings and legs. Additionally, the rubber fingers are gentle on the chicken’s skin, minimizing any potential damage or bruising. Drum pluckers are commonly used in poultry farms, slaughterhouses, and larger-scale chicken processing facilities due to their speed, reliability, and overall effectiveness.

What are the advantages of using a drum chicken plucker compared to manual plucking or other mechanical pluckers?

A drum chicken plucker offers several advantages over manual plucking or other mechanical pluckers:

1. Efficiency: A drum chicken plucker is designed to efficiently remove feathers from multiple chickens at once. It uses rotating rubber fingers on a drum to gently and effectively pluck the feathers, reducing the time and effort required compared to manual plucking.

2. Consistency: With manual plucking, there can be variations in the quality and thoroughness of feather removal. A drum plucker, on the other hand, ensures a consistent and thorough plucking process for each chicken, resulting in a professional and uniform appearance.

3. Gentleness: The rubber fingers used in drum pluckers are designed to be gentle on the chicken’s skin while effectively removing feathers. This helps to minimize any potential damage or bruising that may occur during the plucking process.

4. Time-saving: Drum pluckers are significantly faster compared to manual plucking, allowing users to process a larger number of chickens in less time. This is especially beneficial for commercial poultry processing operations where efficiency and productivity are key factors.

5. Easy to use: Operating a drum plucker is relatively straightforward, requiring minimal training and physical effort. Once the chickens are properly loaded into the drum, the plucking process can be automated, allowing users to focus on other tasks.

6. Easy maintenance: Drum pluckers are generally easy to clean and maintain. The rubber fingers can be easily replaced if damaged, and regular cleaning and sanitization help to prevent any buildup of feathers or debris.

A drum chicken plucker offers superior efficiency, consistency, gentleness, time-saving benefits, ease of use, and easy maintenance compared to manual plucking or other mechanical pluckers.

Are there any specific maintenance or cleaning requirements for a drum chicken plucker to ensure optimal performance and longevity?

Regular maintenance and proper cleaning are essential for ensuring optimal performance and longevity of a drum chicken plucker. Here are some important steps to follow:

1. Regular lubrication: Lubricate the moving parts of the machine according to the manufacturer’s recommendations. This will help reduce friction and prevent wear and tear.

2. Cleaning after each use: Thoroughly clean the drum chicken plucker after every use to remove feathers, dirt, and other debris. Use a hose or pressure washer to rinse off any remaining feathers from the drum and plucker fingers.

3. Inspect and replace worn parts: Regularly inspect the plucker fingers, drive belts, and other components for signs of wear or damage. Replace any worn or damaged parts promptly to ensure optimal performance and prevent further issues.

4. Sanitize the drum: Use a food-grade sanitizer or cleaning solution to sanitize the drum and prevent the growth of bacteria. Make sure to follow the recommended dilution ratios and properly rinse the drum before using it again.

5. Proper storage: When not in use, store the drum chicken plucker in a clean and dry environment. Protect it from exposure to moisture, dust, and direct sunlight.

Remember to always refer to the manufacturer’s manual for specific maintenance and cleaning instructions tailored to your model of drum chicken plucker. Proper maintenance will not only extend the lifespan of your equipment but also ensure safe and efficient operation.

The drum chicken plucker revolutionizes the way we process poultry. Its efficient and highly effective design streamlines the plucking process, saving both time and effort for poultry farmers and processors. With its powerful motor and durable construction, this innovative machine ensures a thorough and clean plucking every time. Whether you’re a small-scale farmer or a large-scale processor, the drum chicken plucker is a must-have tool that elevates productivity and improves overall poultry processing efficiency. Invest in this game-changing technology and experience the difference it makes in your chicken plucking operations.