Contents

A chicken plucker is an essential tool for any poultry farmer or enthusiast. This machine makes the process of removing feathers from a chicken much easier and faster than manual plucking. The plucker is powered by an electric motor, and uses rubber fingers that rotate rapidly to quickly remove feathers from the chicken. The feathers are then collected into a tray beneath the plucker, making cleanup and disposal a breeze.

The chicken plucker is a relatively simple device, but its usefulness is undeniable. Even experienced poultry farmers often find that using a chicken plucker makes the process of preparing a chicken for cooking or butchering much faster and easier. The plucker is also a great time-saver for those who raise chickens for their feathers; the feathers can be collected in bulk and used for crafts or other projects.

Benefits of using a chicken plucker

The benefits of using a chicken plucker are numerous, both for the poultry farmer and for the consumer. For starters, a chicken plucker makes the task of removing feathers from poultry much easier and faster, saving time and labor costs. This is especially true when compared to the traditional method of plucking by hand.

Using a chicken plucker can help farmers to improve the quality of their product, as the feathers are removed more quickly and thoroughly. This in turn helps to reduce the spread of bacteria, which can help to keep the birds healthier.

A chicken plucker also helps to reduce the risk of injury to the hands of the workers. Removing feathers by hand can be a dangerous task, as the sharp points of the feathers can easily penetrate the skin and cause cuts or puncture wounds.

Another benefit of using a chicken plucker is that it helps to minimize the release of feathers into the atmosphere. This is beneficial for both the environment and for the animal welfare. It also helps to reduce the amount of dust and debris that can be stirred up while plucking by hand.

Finally, a chicken plucker can help to improve the efficiency of the poultry processing line, as the plucking process can be completed in a fraction of the time it would take to remove the feathers by hand. This can help to reduce the cost of production, making it more cost-effective for the farmer.

All in all, the benefits of using a chicken plucker are numerous, and can help to make the plucking process safer, faster, and more efficient.

Overall, the chicken plucker is a great addition to any poultry farmer or enthusiast’s toolkit. This machine makes the process of preparing a chicken for cooking or butchering much faster and easier, and reduces the risk of injury or infection from manual plucking. With a chicken plucker, you can make sure that your poultry products are ready for consumption in no time.

How to pluck a chicken?

Plucking a chicken is a skill that is essential for anyone who is raising chickens for meat, or who likes to save money by preparing poultry themselves. With a little practice and the right technique, you can pluck a chicken with ease and minimal mess.

Scald the chicken

The first step is to scald the chicken. Scalding loosens the feathers, making them easier to pluck. Place the chicken in a large pot of hot water, heated to about 150-160°F. Leave the chicken in the water for about a minute, then remove it and let it cool.

Plucking the Feathers

Once the chicken is cool enough to handle, begin plucking the feathers. Start at the neck, and pull the feathers in the direction of the grain. Continue plucking in a circular motion, moving from the neck to the tail. Some feathers will come out easily, while others may need a bit more effort. If you encounter any stubborn feathers, try using a pair of poultry shears to cut them out.

Cut out any remaining pin feathers

Once the majority of the feathers are removed, you can use a razor blade or poultry shears to cut out any remaining pin feathers. Be careful not to cut the skin, as this can cause the chicken to spoil.

Remove the entrails

Finally, remove the entrails and rinse the chicken with cold water. Your chicken is now ready to be cooked and enjoyed.

Plucking a chicken may seem like a daunting task, but with patience and the right technique, it can be done quickly and easily. So don’t be intimidated – give it a try!.

What is a chicken plucker?

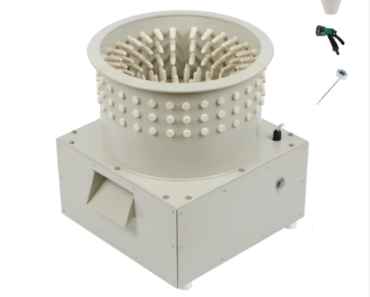

A chicken plucker is an essential tool for anyone who is raising chickens for meat or eggs. It is a machine used to remove the feathers from a chicken in the process of butchering poultry. It is composed of a large drum with rubber fingers that spin rapidly to remove the feathers from the chicken. The rubber fingers will not harm the bird, but the plucking process should be done quickly to prevent the bird from becoming distressed. The feathers are then collected and can be used for other purposes such as stuffing pillows or making quill pens.

The chicken plucker is an incredibly useful tool that saves a lot of time and energy when compared to plucking the bird by hand. It is a much more efficient way to process chickens, and it also reduces the amount of waste that is created. By using a chicken plucker, you can process a chicken in a matter of minutes rather than the hours it would take to do it by hand. This makes it the perfect tool for commercial use or for those who are raising chickens in their own backyard.

Overall, a chicken plucker is an essential tool for anyone who is processing poultry, whether it is for commercial use or for their own personal use. It is a quick, efficient, and mess-free way to remove the feathers from a chicken and can save a lot of time and energy in the process.

Can you skin a chicken instead of plucking?

Yes! Skinning a chicken is a much quicker way to remove feathers from a bird than plucking, and it’s also a great way to reduce waste and get the most out of your poultry.

When skinning a chicken, you’ll want to start by cutting around the neck of the bird with a sharp knife. Then you’ll need to cut through the skin around the legs and wings, taking extra care not to cut into the meat. Once you have those areas opened up, you can start to pull the skin away from the body of the chicken. Pull firmly but carefully to avoid tearing the skin.

Continue to pull the skin away from the body of the bird until it is completely removed. You may need to use a pair of pliers to pull off the skin from the feet and wings, as these areas can be particularly difficult to remove. Once the skin is removed, you can discard it or save it to make stock or soup.

The benefits of skinning a chicken instead of plucking it are numerous. It’s much quicker and easier than plucking, and it also reduces the amount of waste you produce. Skinning also allows you to make use of the entire chicken, from the skin to the meat and bones.

So the next time you’re preparing a chicken for dinner, consider skinning it instead of plucking it. It’s a great way to reduce waste, get the most out of your poultry, and get dinner on the table in no time!

How does a chicken plucker work

The process of manually plucking feathers from a bird can be a laborious and time-consuming task, so the invention of the chicken plucker has revolutionized the poultry industry.

The process of the chicken plucker is quite simple. The machine consists of a rotating drum that is filled with rubber fingers. The rubber fingers are spaced evenly around the circumference of the drum, and are designed to mimic the motion of a person manually plucking a bird. The drum is then activated, and as it rotates, the rubber fingers agitate the feathers of the bird, causing them to fall away from the body.

The process of the chicken plucker is actually quite gentle, and does not harm the body of the bird in any way. In fact, the machine is designed to be gentle enough to allow the bird to be reused for food afterwards. This has made the chicken plucker an invaluable tool in the poultry industry, as it allows for the rapid and efficient removal of feathers from a bird.

The chicken plucker is a remarkable invention that has saved countless hours of labor in the poultry industry. It is capable of quickly and efficiently removing the feathers from a bird, while also being gentle enough to not damage the body of the bird. Without the chicken plucker, the poultry industry would not be where it is today.

How many RPM does a chicken plucker run

Generally speaking, most chicken pluckers will range from 500 to 2000 RPMs. The number of RPMs (revolutions per minute) that a chicken plucker runs depends on several factors, including the size and type of plucker, the type of feathers being removed, and the desired results.

The speed at which a chicken plucker runs also depends on how quickly you need to process the chickens. If you’re looking to quickly process a large number of chickens, you’ll likely want to run your plucker at higher RPMs. On the other hand, if you’re looking for a more delicate job, such as removing feathers from a small breed or breed of chicken with very fragile feathers, you’ll likely want to run your plucker at lower RPMs.

The number of RPMs a chicken plucker runs depends on various factors and can range from 500 to 2000 RPMs. When choosing the best RPM for your plucker, it is important to consider the size and type of plucker, the type of feathers being removed, and the desired results.

What motor to use for a chicken plucker

When it comes to finding the right motor for a chicken plucker, there are a few key considerations. The first is power. Depending on the size of the chickens you are plucking, you will need a motor that can generate enough torque to effectively and efficiently pull the feathers off the bird. If you are plucking large birds, you may need a motor with a higher power rating.

The second consideration is speed. The faster the motor, the more efficient it will be at plucking. If you are plucking large birds, a higher speed is recommended. If you are plucking smaller birds, however, a lower speed may be better since it will reduce the risk of damaging the bird.

The third consideration is cost. You want to make sure that you are getting the most bang for your buck when it comes to motor selection. If you are looking for a motor that is powerful, relatively quiet, and cost effective, then you may want to look at electric motors. These are typically more cost effective than gas motors and can offer a good performance at a lower price.

Finally, you will want to make sure that your motor is designed to handle the specific requirements of a chicken plucker. This means that the motor should be able to handle the additional weight of the feathers and the vibration of the plucker. A motor designed for a specific chicken plucker can help you get the best performance out of your machine.

When it comes to finding the right motor for a chicken plucker, there are a few key considerations to keep in mind. You want to make sure that the motor is powerful enough to effectively and efficiently pull the feathers off the bird, is fast enough to pluck it efficiently, is cost effective, and is designed to handle the specific requirements of a chicken plucker.

How many HP do you need for a chicken plucker

The most basic chicken pluckers tend to require 1-2 HP, but more advanced and industrial-grade pluckers can require up to 15 HP. It is important to note that the amount of HP needed for a chicken plucker is not the only factor you should consider. You should also research the size and weight of the plucker, as well as the amount of feathers it is designed to remove.

When considering how much horsepower (HP) you need for a chicken plucker, it is important to understand that not all chicken pluckers are the same. Each one is designed to work differently, so the amount of HP required can vary greatly. Generally speaking, the larger the plucker and the more feathers it is designed to remove, the more HP it will require.

The amount of HP required for a chicken plucker also depends on the type of motor you use. Electric motors generally require less HP than gas motors, and they tend to be more efficient and cost-effective. Additionally, if you plan to use a plucker in an industrial setting, you should consider using a hydraulic motor, which can provide a higher level of power and performance.

The amount of HP you need for a chicken plucker varies greatly depending on the size, weight, and design of the plucker, as well as the type of motor you use. If you are looking to purchase a chicken plucker, it is important to do your research and find the one that best suits your needs.