Contents

- 1 The Ultimate Guide to Chicken Defeathering with Chicken Plucker

- 2 Starpluck SP-1 Chicken Plucker In Action.

- 3 The Importance of Chicken Defeathering

- 4 Efficient Chicken Defeathering Techniques

- 5 The Benefits of Proper Chicken Defeathering

- 6 FAQ

- 6.1 How does a chicken plucker effectively remove feathers without damaging the skin?

- 6.2 What is the ideal temperature and duration for defeathering chickens using a chicken plucker?

- 6.3 Are there any safety precautions or equipment recommendations when using a chicken plucker for defeathering?

- 6.4 Related Posts

Discover the art of chicken defeathering and take your poultry processing to the next level! Here, we delve into the essential techniques of chicken plucking, exploring effective methods and time-saving tips to achieve feather-free results. Don’t miss out on this comprehensive guide for an impeccable plucking process.

The Ultimate Guide to Chicken Defeathering with Chicken Plucker

Feathers can be quite challenging to remove from chickens, especially when done manually. Thankfully, the Chicken Plucker provides an efficient solution. With its powerful motor and strategically positioned rubber fingers, it effortlessly removes feathers from chickens in no time.

Step 1: Preparation

Before getting started, make sure your Chicken Plucker is clean and in good working condition. Inspect the rubber fingers for any damage or wear and tear. Also, ensure that the plucking area is free from any debris or contaminants.

Step 2: Scalding

Scalding the chicken before using the Chicken Plucker is an essential step. This softens the feathers, making them easier to remove. Fill a large pot with hot water (around 150°F) and immerse the chicken for approximately 2-3 minutes. Make sure the entire bird is submerged.

Step 3: Plucking

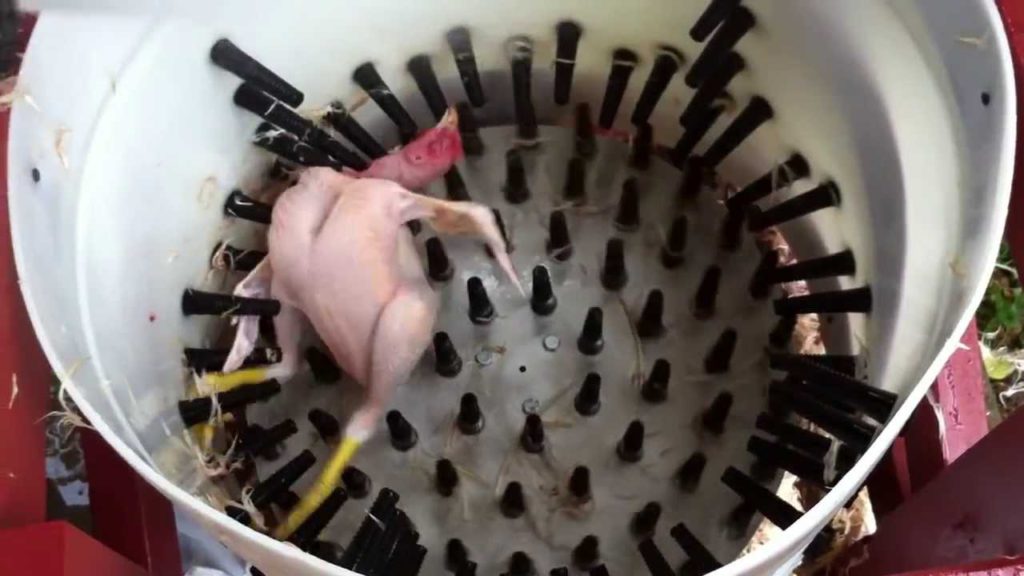

With the chicken properly scalded, it’s time to use the Chicken Plucker. Place the chicken in the plucker, making sure it fits securely. Turn on the device and let the rubber fingers do their magic. The rotation and movement of the rubber fingers will effectively remove the feathers, leaving behind a perfectly defeathered chicken.

Step 4: Finishing Touches

After the initial plucking process, check for any remaining feathers or missed spots. Remove these by hand or use a pair of pliers if necessary. Once completely defeathered, rinse the chicken thoroughly to remove any residual feathers or debris.

Step 5: Cleaning and Maintenance

After each use, it’s essential to clean the Chicken Plucker thoroughly. Remove any feathers or debris that may have collected during the plucking process. Wipe down the device with a damp cloth and ensure it is stored in a clean and dry place.

Conclusion

Using the Chicken Plucker significantly simplifies the chicken defeathering process. With its efficiency and convenience, poultry farmers and enthusiasts can now enjoy more time and energy savings. Follow this guide step-by-step, and you’ll be able to defeather chickens like a pro using the incredible Chicken Plucker.

Starpluck SP-1 Chicken Plucker In Action.

The Importance of Chicken Defeathering

Defeathering chickens is a crucial step in the chicken processing industry. This process, also known as plucking, involves removing the feathers from the chicken’s body after it has been slaughtered. Here, we will explore why chicken defeathering is significant and the various methods used in the Chicken Plucker industry.

Efficient Chicken Defeathering Techniques

Efficiency plays a key role in the Chicken Plucker industry, as large numbers of chickens are processed daily. To ensure optimal productivity, various techniques have been developed for chicken defeathering:

- Scalding: The chicken is first immersed in hot water to loosen the feathers, making them easier to remove.

- Poultry Pluckers: These automated machines have rubber fingers or discs that gently rub against the chicken’s skin, effectively removing the feathers.

- Manual Plucking: In smaller-scale operations, chickens may be hand-plucked using specialized tools such as plucking machines or turkey pluckers.

The Benefits of Proper Chicken Defeathering

Proper chicken defeathering offers several benefits:

- Improved Hygiene: Removing feathers ensures cleaner poultry products, reducing the risk of bacterial contamination during storage and transportation.

- Better Presentation: Defeathering contributes to the aesthetic appeal of chicken products, making them visually more appealing to consumers.

- Efficient Further Processing: Feather-free chickens are easier to handle during subsequent processing stages, such as evisceration and portioning.

- Reduced Processing Time and Costs: Effective chicken defeathering techniques minimize the time and labor required for feather removal, leading to increased operational efficiency and cost savings.

FAQ

How does a chicken plucker effectively remove feathers without damaging the skin?

A chicken plucker effectively removes feathers without damaging the skin through a combination of mechanical and water-based methods. The plucking process typically involves placing the chicken inside a rotating drum or tank that is equipped with rubber fingers or soft rubber discs. As the drum rotates, the rubber fingers or discs gently pull out the feathers from the bird’s skin.

The rotation of the drum, combined with the movement of the rubber fingers or discs, creates a frictional force that helps to loosen and remove the feathers from the skin without causing any damage. Additionally, many chicken pluckers incorporate water into the process to help facilitate feather removal.

The presence of water helps to lubricate the feathers, making them easier to remove without pulling or tearing the skin. Water also acts as a barrier between the rubber fingers or discs and the skin, reducing the risk of abrasions or other forms of damage.

Overall, the design and careful engineering of chicken pluckers aim to strike a balance between efficient feather removal and skin protection. By using gentle mechanical methods and incorporating water, these machines effectively remove feathers while minimizing the risk of skin damage.

What is the ideal temperature and duration for defeathering chickens using a chicken plucker?

The ideal temperature for defeathering chickens using a chicken plucker is around 130 to 140 degrees Fahrenheit (54 to 60 degrees Celsius). This temperature range helps to loosen the feathers without cooking the meat.

As for the duration, it largely depends on the size and condition of the chicken. Generally, it takes about 20-30 seconds to effectively remove the feathers from a properly scalded chicken. However, larger chickens or those with tougher feathers may require slightly longer time. It’s important to monitor the process closely and stop when the feathers are completely removed without damaging the skin.

Are there any safety precautions or equipment recommendations when using a chicken plucker for defeathering?

When using a chicken plucker for defeathering, it is important to take certain safety precautions and use appropriate equipment. Here are some recommendations:

1. Protective Clothing: Wear a pair of heavy-duty gloves to protect your hands from any sharp feathers or moving parts. It is also advisable to wear protective eyewear to shield your eyes from flying debris.

2. Secure Work Area: Set up your chicken plucker in a well-ventilated area with sufficient space to maneuver. Make sure the machine is placed on a stable surface and won’t tip over during operation.

3. Read the Manual: Familiarize yourself with the manufacturer’s instructions and guidelines before using the chicken plucker. Follow the recommended operating procedures and safety precautions mentioned in the manual.

4. Inspect the Equipment: Before each use, thoroughly inspect the plucker for any signs of damage or wear. Ensure that all parts, such as fingers or fingers disks, are properly attached and in good condition.

5. Slowing Down the Birds: Prior to placing chickens into the plucker, it is recommended to stun or restrain them properly to minimize their movement during the process. This can help reduce the risk of injury to both the bird and the operator.

6. Supervision: Always supervise the operation of the chicken plucker. Avoid leaving it unattended while it is running to prevent any accidents or mishaps.

7. Clean and Maintain: After each use, clean the plucker thoroughly following the manufacturer’s instructions. Regularly inspect and maintain the machine to ensure optimal performance and safe operation.

Remember, these recommendations are general safety precautions, and it’s essential to refer to the specific guidelines provided by the manufacturer for your particular chicken plucker model.

Chicken defeathering plays a crucial role in the efficiency and productivity of the Chicken Plucker process. The chicken plucking machine significantly reduces time and effort by automating the feather removal process. This not only enhances overall workflow but also ensures consistent and hygienic results. By investing in a quality Chicken Plucker, poultry farmers can optimize their operations, improve yield, and maintain high standards of meat quality. With its effectiveness, accuracy, and convenience, chicken defeathering using Chicken Plucker machines is undoubtedly a game-changer in the poultry industry.