Contents

- 1 Enhancing Efficiency: The Revolutionary Feather Plate Technology in Chicken Pluckers

- 2 What is a chicken plucker feather plate?

- 3 Benefits of using a high-quality feather plate

- 4 Tips for choosing the right feather plate

- 5 FAQ

- 5.1 How does the feather plate on a chicken plucker work to effectively remove feathers from poultry?

- 5.2 What are some key features to look for in a feather plate for a chicken plucker to ensure efficient and thorough feather removal?

- 5.3 Are there any specific maintenance or cleaning procedures recommended for the feather plate on a chicken plucker to prolong its lifespan and optimize performance?

- 5.4 Related Posts

Discover the Magic of Chicken Plucker Feather Plate: Get ready to revolutionize your poultry processing with the incredible efficiency and precision of the chicken plucker feather plate. This essential component of any chicken plucking machine ensures optimal feather removal, saving you time and effort. Join us as we delve into the nitty-gritty of how this ingenious invention works and why it’s a game-changer in the world of chicken plucking. Don’t miss out on this informative read!

Enhancing Efficiency: The Revolutionary Feather Plate Technology in Chicken Pluckers

Chicken plucking has always been a time-consuming and labor-intensive process, requiring manual removal of feathers from each bird. However, thanks to the revolutionary feather plate technology in modern chicken pluckers, this task has become significantly more efficient and streamlined.

Feather plate technology refers to the advanced mechanism used in chicken pluckers to effectively remove feathers from poultry. Traditional pluckers relied on manual labor or old-fashioned rubber fingers to accomplish this task, resulting in slower processing times and less-than-perfect results.

The revolutionary feather plate technology incorporates specially designed plates with strategically placed fingers that mimic the natural motion of hand plucking. These fingers are made from durable materials such as rubber or silicone, ensuring a gentle yet effective plucking process.

The key advantage of this feather plate technology is its ability to enhance efficiency in chicken plucking operations. The specialized plates with their precisely positioned fingers allow for simultaneous plucking of multiple feathers, saving time and effort. This means that more chickens can be processed in a shorter span of time, increasing overall productivity.

Furthermore, the revolutionary feather plate technology ensures a higher plucking accuracy. The uniquely designed fingers firmly grip the feathers, minimizing the chances of leaving behind any residue. This leads to a cleaner and more presentable final product, meeting the quality standards expected by consumers and businesses alike.

In addition to boosting efficiency, the feather plate technology also contributes to improved worker safety. By automating the plucking process, it reduces the need for manual intervention and limits the risks associated with repetitive and strenuous tasks. This allows employees to focus on other essential aspects of poultry processing, enhancing overall workplace safety.

The revolutionary feather plate technology in chicken pluckers has revolutionized the efficiency of poultry processing. Its advanced mechanism and precisely positioned fingers enable faster plucking times, higher accuracy, and improved worker safety. As the industry continues to evolve, this technology will undoubtedly play a crucial role in meeting the growing demand for efficiently processed, high-quality chicken products.

What is a chicken plucker feather plate?

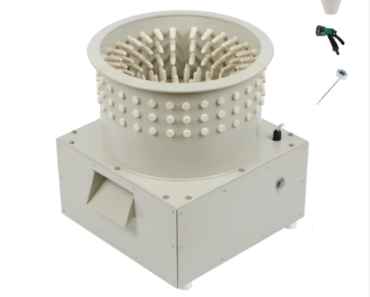

The chicken plucker feather plate is an integral component of a chicken plucking machine. It is a circular plate that is typically made of durable materials such as stainless steel or rubber. The main purpose of the feather plate is to effectively remove feathers from the chicken during the plucking process.

The feather plate has a series of strategically placed rubber fingers or bristles that help grab and pull the feathers as the machine rotates. These bristles are designed to mimic the motion of a bird preening its feathers, ensuring a thorough and efficient plucking process.

It is important to choose a feather plate that is compatible with the specific chicken plucker machine being used. The size and shape of the plate should match the machine’s specifications to ensure optimal performance.

Benefits of using a high-quality feather plate

Using a high-quality feather plate in a chicken plucker machine offers several benefits:

1. Efficient feather removal: A well-designed feather plate with sturdy bristles ensures efficient feather removal, reducing the time and effort required for plucking chickens.

2. Improved hygiene: A good feather plate can effectively remove feathers without damaging the chicken’s skin. This helps maintain hygiene by minimizing the risk of contamination from leftover feathers.

3. Long-lasting performance: High-quality feather plates are made from durable materials that can withstand continuous use. They are less likely to break or wear out, ensuring consistent and reliable performance over time.

4. Easy maintenance: Feather plates are relatively easy to clean and maintain. They can be easily removed from the plucker machine for cleaning or replacement.

Tips for choosing the right feather plate

When selecting a feather plate for your chicken plucker machine, consider the following factors:

1. Compatibility: Ensure that the feather plate is compatible with your specific chicken plucker machine. Check the size, shape, and mounting system to ensure a proper fit.

2. Material quality: Opt for a feather plate made from high-quality materials such as stainless steel or rubber. These materials are durable, easy to clean, and resistant to corrosion.

3. Bristle design: Look for a feather plate with well-designed bristles that can effectively grip and remove feathers without damaging the chicken’s skin.

4. Customer reviews: Read customer reviews and ratings to get an idea of the performance and durability of the feather plate you are considering. This can help you make an informed decision.

By choosing the right feather plate for your chicken plucker machine, you can ensure efficient and effective feather removal, saving time and effort in the poultry processing process.

FAQ

How does the feather plate on a chicken plucker work to effectively remove feathers from poultry?

The feather plate on a chicken plucker works by creating a mechanical force that effectively removes feathers from poultry. The feather plate, also known as the plucking plate or plucking fingers, is made up of multiple protruding rubber or rubber-like fingers. These fingers are strategically positioned in rows and spaced closely together on the plate.

When the chicken is placed inside the plucker and the machine is turned on, the rotating motion of the plucking plate creates a powerful suction effect. This causes the feathers to be pulled towards the plate and firmly held by the flexing rubber fingers. The rotation speed and design of the plate ensure that the feathers are caught between the fingers and are effectively pulled out as the chicken rotates against it.

The flexibility of the rubber fingers allows them to conform to the shape of the poultry, ensuring that the feathers are gripped tightly but without damaging the skin. The combination of the suction force and the grip of the fingers ensures that the feathers are efficiently and thoroughly removed from the bird’s body.

Overall, the feather plate on a chicken plucker is designed to provide an effective and efficient solution for removing feathers from poultry, saving time and effort compared to manual plucking methods.

In summary, the feather plate on a chicken plucker uses rotating rubber fingers to create a suction force that effectively removes feathers from poultry. The flexible fingers grip the feathers tightly without damaging the skin, resulting in efficient and thorough plucking.

What are some key features to look for in a feather plate for a chicken plucker to ensure efficient and thorough feather removal?

When looking for a feather plate for a chicken plucker, there are several key features to consider to ensure efficient and thorough feather removal.

1. Material: The feather plate should be made of durable and corrosion-resistant material, such as stainless steel or food-grade rubber, to withstand the repetitive use and harsh conditions of poultry processing.

2. Design: Look for a feather plate that has evenly spaced and sharp fingers or fingers with gentle serrations. This design allows for effective grabbing and pulling of feathers from the chicken’s skin.

3. Size and Density: The feather plate should be appropriately sized to accommodate the size of the chickens you will be processing. Additionally, the density of the fingers should be sufficient to effectively remove feathers without causing excessive damage to the chicken’s skin.

4. Easy to clean: Choose a feather plate that is easy to clean and maintain. Removable plates or those with smooth surfaces make it convenient to remove feathers and debris, ensuring proper hygiene and preventing cross-contamination.

5. Compatibility: Ensure that the feather plate is compatible with your specific chicken plucker model. Different pluckers may have varying attachment mechanisms, so it’s essential to check compatibility before making a purchase.

By considering these key features, you can select a high-quality feather plate that will efficiently and thoroughly remove feathers from chickens during the plucking process.

Are there any specific maintenance or cleaning procedures recommended for the feather plate on a chicken plucker to prolong its lifespan and optimize performance?

To maintain and prolong the lifespan of the feather plate on a chicken plucker and optimize its performance, it is recommended to follow the following maintenance and cleaning procedures:

1. Regular Cleaning: After each use, thoroughly clean the feather plate by removing any debris or feathers stuck in the surface. Use a brush or scraper to remove any stubborn particles. Clean it with warm soapy water or a mild detergent to remove grease and dirt.

2. Sanitization: Ensure that the feather plate is properly sanitized before every use to minimize the risk of bacterial contamination. You can use a sanitizing solution recommended for food processing equipment and follow the manufacturer’s instructions.

3. Inspect for Damage: Regularly inspect the feather plate for any signs of wear, cracks, or damage. If any issues are detected, it is essential to replace the plate immediately to prevent further damage and ensure optimal performance.

4. Lubrication: Apply food-grade lubricant or oil to the moving parts of the plucker, including the feather plate, as recommended by the manufacturer. This helps reduce friction and ensures smooth operation.

5. Storage: When not in use, store the chicken plucker and its feather plate in a clean, dry, and protected environment. This protects it from dust, moisture, and other contaminants that may affect its performance.

Remember to always refer to the manufacturer’s guidelines and instructions for specific maintenance and cleaning recommendations for your chicken plucker model.

The chicken plucker feather plate is undeniably a crucial component in the efficient and effective work of a chicken plucker. Its purpose of gently removing feathers through its strategically designed fingers cannot be understated. The durability and quality of the feather plate greatly affect the overall performance and longevity of the machine. It is essential to invest in a feather plate that is made from high-quality materials to ensure optimal plucking results. By purchasing a reliable feather plate, poultry farmers can save valuable time and effort in their chicken plucking operations. Remember, a well-maintained feather plate will contribute to a smooth and hassle-free plucking process, ultimately leading to a higher production yield.